Weight matters when it comes to construction. Traditional fill materials like soil and gravel can add unnecessary stress to weak soils and lead to settling, shifting and costly repairs. That’s where Geofoam comes in. It’s a lightweight but strong material that’s changing the way engineers handle construction challenges.

At Benchmark Foam, we manufacture high-quality Geofoam, a closed-cell expanded polystyrene (EPS) product designed for geotechnical applications. Lighter than traditional fill by 50 to 100 times, Geofoam provides stability without the heavy load, making it ideal for roads, bridges, embankments and more.

Why Engineers Choose Geofoam

1. Lightweight Strength

Geofoam weighs just 1 to 3 pounds per cubic foot compared to 100+ pounds for soil. This means:

- Less stress on weak soils: Preventing sinkage and uneven settling.

- Lower pressure on retaining walls: Extending their lifespan.

- Easier transportation and installation: Cutting project time and labor costs.

2. Soil Stabilization Made Easy

Unstable ground is a common headache in construction. Geofoam solves this by doing the following:

- Providing a solid base: Even on soft or uneven terrain.

- Preventing slope failures: Keeping embankments secure.

- Supporting heavy structures: Without adding excessive weight.

3. Faster, Cleaner Construction

Unlike dirt or gravel, Geofoam arrives in pre-cut blocks, ready to install. No compaction, no waiting for settlement. Ease of install that keeps projects on schedule.

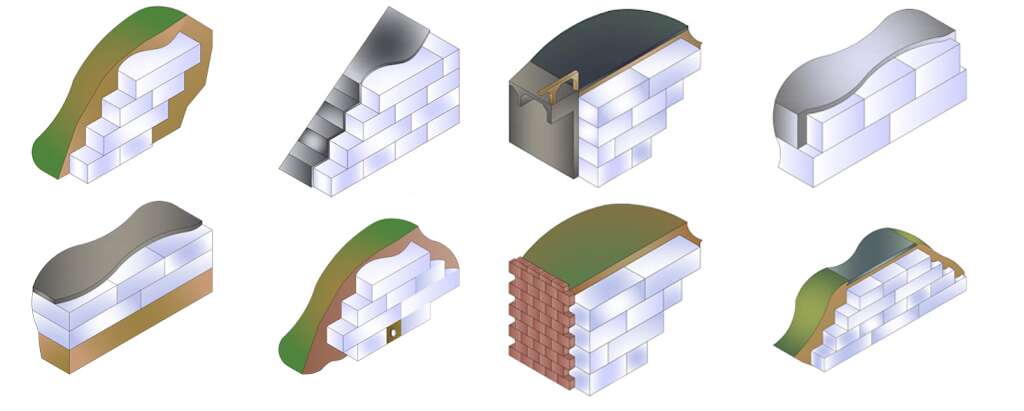

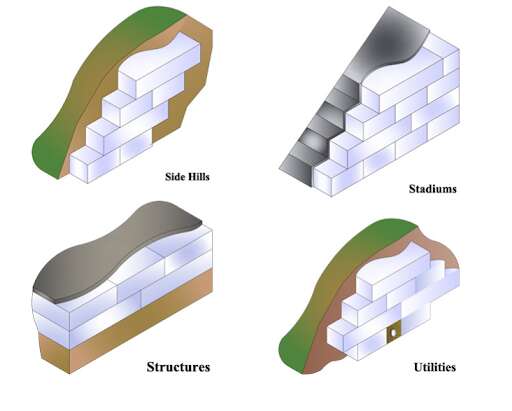

Where Geofoam Excels

Road & Highway Construction

Roads built on weak soils often crack and sink over time. Geofoam:

- Reduces ground pressure: Preventing pavement failures.

- Insulates against frost heave: Keeping roads smooth in freezing climates.

- Speeds up repairs: Minimizing traffic disruptions.

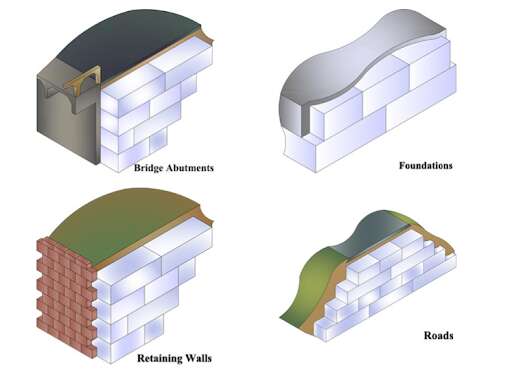

Bridge Abutments & Retaining Walls

Heavy fill materials can push against walls, causing cracks or collapses. Geofoam’s lightweight support eases this strain by improving durability.

Tunnels & Underground Projects

In tunnel construction, Geofoam:

- Fills voids securely: Without compacting over time.

- Reduces lateral pressure: Protecting tunnel walls.

- Resists moisture: Unlike materials that degrade underground.

Landscaping & Embankments

Building on steep or unstable slopes? Geofoam creates a stable foundation for terracing, green spaces and infrastructure without shifting.

Environmental Benefits of Geofoam

Sustainability is a growing concern in construction and Geofoam delivers:

- No harmful chemicals: Free from CFCs, HCFCs and ozone-depleting substances.

- Long-lasting performance: Won’t rot, decompose or leach into soil.

Custom Solutions for Any Project

At Benchmark Foam, we supply Geofoam in standard and custom-cut blocks to fit exact project needs. Our material meets ASTM D6817 standards, guaranteeing consistency and reliability.

Whether you’re working on a highway, bridge or underground utility, Geofoam offers a smarter, lighter and more efficient alternative to traditional fill.

Ready to build smarter with Geofoam? Contact Benchmark Foam today.