Contractors face a tough choice when building on unstable ground: spend weeks (and a small fortune) moving heavy soil, or find a better way. That’s where Geofoam blocks shine. These lightweight yet sturdy EPS (expanded polystyrene) blocks are changing the game in construction, offering a simpler, faster, and more cost-effective solution for projects that need reliable support without the backbreaking labor.

At Benchmark Foam, we manufacture Geofoam to help engineers and builders tackle tricky sites with confidence. Here’s how it works and why it’s becoming a go-to material for roads, bridges, embankments, and more.

What Are Geofoam Blocks?

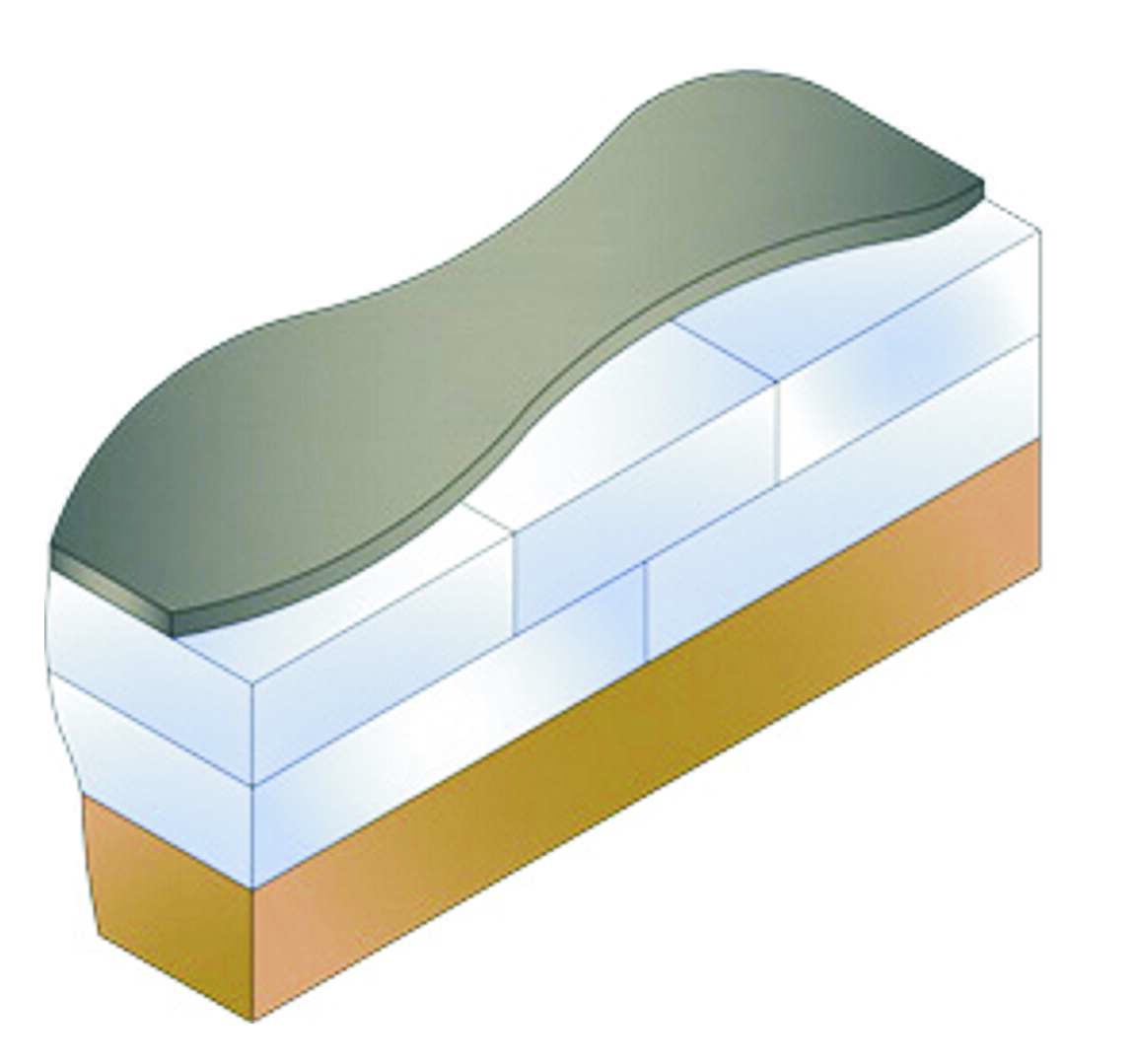

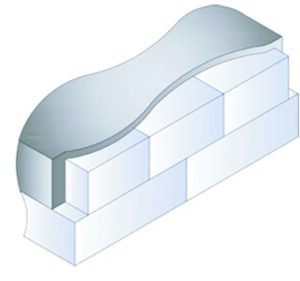

Geofoam is a lightweight, rigid foam material made from expanded polystyrene (EPS). Unlike traditional fill like dirt or gravel, it weighs 50 to 100 times less while still providing impressive strength. That means crews can move and place it quickly. No bulldozers, compactors or long settling periods required.

Key Features:

- Lightweight: Easy to handle, reducing labor and equipment costs.

- Strong: Supports heavy loads without sinking or shifting.

- Weather-resistant: Won’t break down from moisture, frost, or temperature swings.

- Custom-cut: Can be shaped onsite to fit exact project needs.

How Geofoam Blocks Improve Construction Efficiency

1. Faster Installation = Shorter Project Timelines

Traditional fill materials take time to haul, compact and settle. Geofoam skips those steps.

- No compaction needed: Unlike soil, it’s ready to build on immediately.

- Easy to transport: A single truck can carry a full load, reducing trips.

- Quick placement: Crews stack blocks like giant LEGOs, cutting weeks off schedules.

2. Saves Money on Labor & Equipment

Heavy machinery isn’t cheap and neither is labor. Geofoam reduces the need for:

- Excavators

- Compactors

- Extra hauling trucks

Since it’s lighter and easier to handle, crews can often place it by hand or with minimal equipment.

3. Solves Problem Soils Without the Headaches

Soft, wet, or uneven ground can derail a project. Geofoam provides a stable base where traditional fill would sink or shift.

- Prevents settlement: Keeps roads, bridges and foundations level.

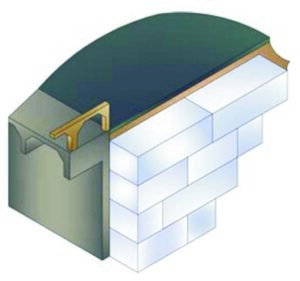

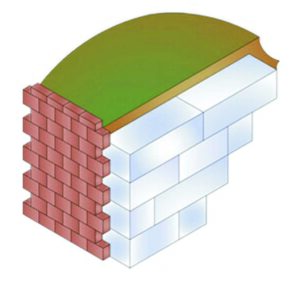

- Reduces pressure on retaining walls: Less weight means less stress on structures.

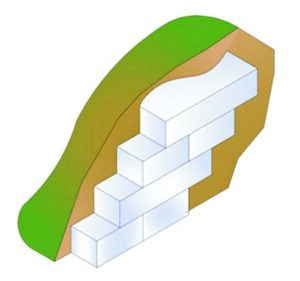

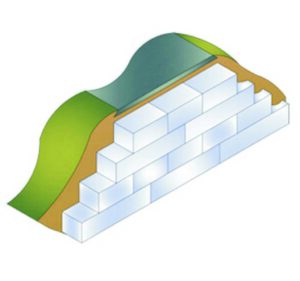

- Works on slopes: Stops erosion and stabilizes uneven terrain.

4. Insulates Against Frost & Temperature Swings

In cold climates, freezing ground can buckle pavement and crack foundations. Geofoam acts as a thermal barrier, preventing frost heave and extending the life of roads and structures.

5. Eco-Friendly & Recyclable

Unlike some construction materials, Geofoam is:

- Non-toxic: No harmful chemicals or leaching.

- Ozone-safe: Free from CFCs and HCFCs.

- Recyclable: Can be repurposed after use.

Where Geofoam Blocks Excel

Highway & Road Construction:

- Lightweight fill for embankments

- Insulation under pavement to prevent frost damage

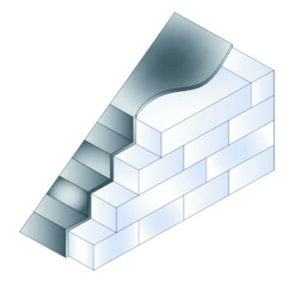

Bridge Abutments & Retaining Walls:

- Reduces lateral pressure, improving stability

Landscaping & Slope Stabilization:

- Prevents erosion on steep grades

Underground Projects (Tunnels, Utilities):

- Supports structures without adding excessive weight

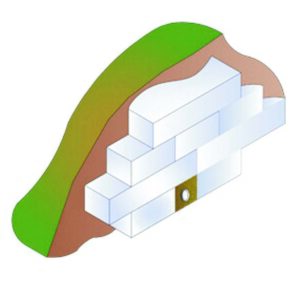

Void Filling:

- Quickly fills sinkholes, abandoned pipelines, or uneven terrain

Why Choose Benchmark Foam for Geofoam?

We don’t just sell Geofoam, we help you use it right. Our team works with engineers and contractors to:

- Custom-cut blocks for exact project specs.

- Meet ASTM D6817 standards for consistent quality.

- Provide full specifications and support

Build Smarter with EPS Geofoam

Not only are Geofoam blocks a substitute for dirt, they’re a better way to build. Faster, lighter and more cost-effective, they’re helping contractors finish projects on time and under budget, even on challenging sites.

Want to see how Geofoam can work for your next job?

Contact Benchmark Foam for a quote.