If you’ve ever unboxed a fragile electronic device or received a temperature-sensitive medical shipment in perfect condition, you’ve likely experienced the magic of EPS custom packaging firsthand. Expanded Polystyrene (EPS) molding represents one of the most effective methods for creating protective packaging solutions that seem to defy their own weight. At Benchmark Foam, we’ve spent years perfecting the art of transforming polystyrene beads into reliable packaging systems that businesses across industries depend on.

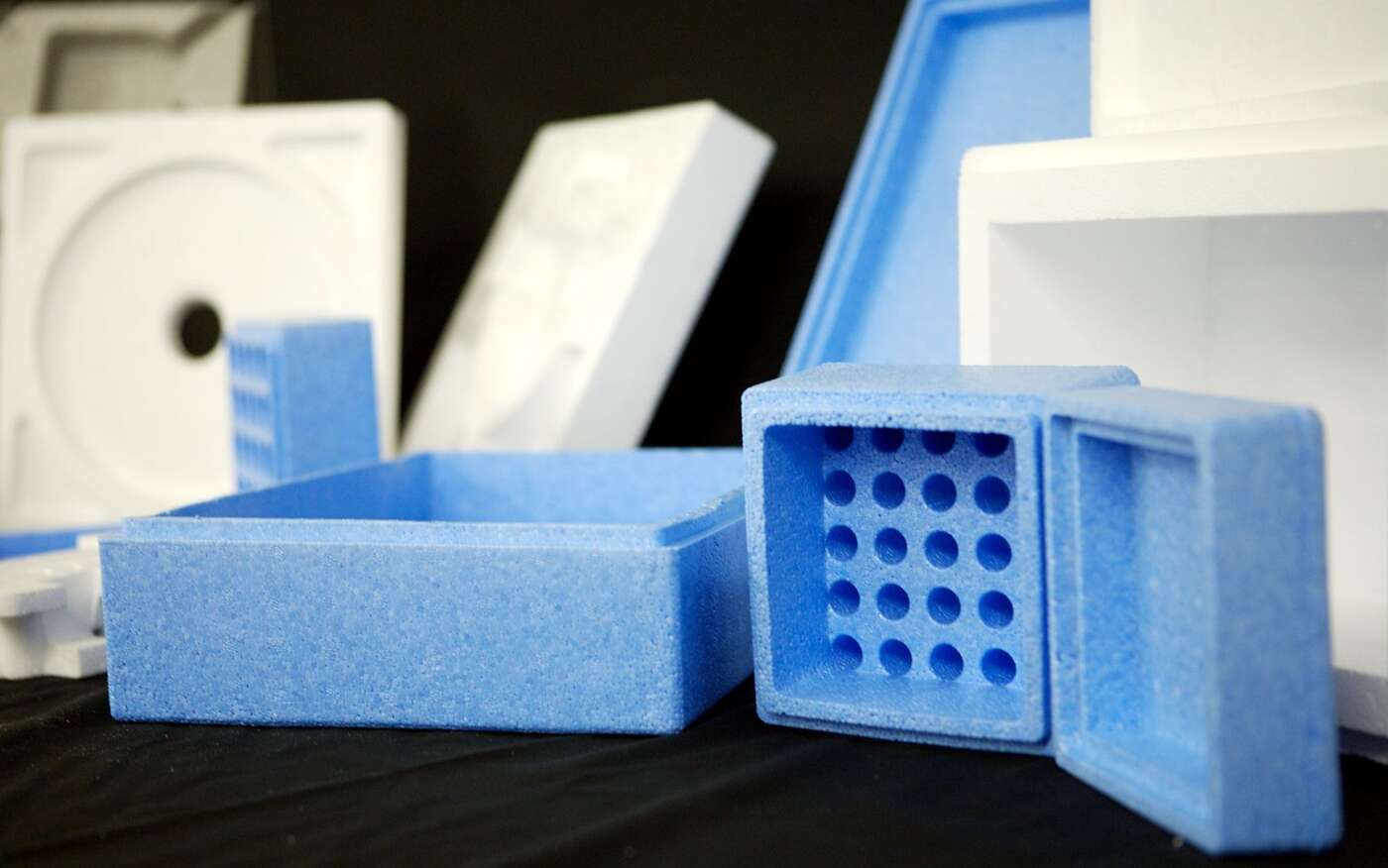

What makes EPS custom packaging so special? It’s more than just a foam box. It’s a protective environment that hugs every contour of your product, absorbs impacts that would otherwise cause damage and does so without adding unnecessary weight or cost. This unique combination of qualities has made EPS molding the preferred choice for companies looking to balance product protection with operational efficiency.

The EPS Molding Process

The process of EPS molding begins with tiny polystyrene beads containing a blowing agent called pentane. These beads expand up to fifty times their original size when exposed to steam and become lightweight, closed-cell foam particles. These expanded beads are then placed into custom-designed molds where steam is applied again, fusing them together into specific shapes that match your product’s exact dimensions.

This molding process allows for remarkable precision, whether you’re creating packaging for delicate glass components, sensitive electronic devices or irregularly shaped industrial parts. The ability to create these custom forms is what sets EPS apart from generic packaging materials like loose fill peanuts or cardboard inserts, which simply can’t provide the same level of tailored protection.

The Lightweight Advantage

One of the largest benefits of EPS custom packaging is its strength-to-weight ratio. EPS consists of approximately 98% air, making it lightweight yet surprisingly strong. This lightness translates directly to transportation savings. It reduces shipping costs and fuel consumption while potentially lowering your carbon footprint.

Consider this: reducing packaging weight by just 10% can yield substantial reductions in transportation fuel consumption and associated greenhouse gas emissions. For businesses shipping large volumes of products, these savings compound quickly and affect both the bottom line and environmental impact statements. Unlike heavier packaging materials like wood or corrugated paper, EPS provides ideal protection without the added cost of weight.

Engineered Impact Resistance

The closed-cell structure of molded EPS creates a cellular matrix that excels at absorbing and dispersing energy from impacts. When a packaged product experiences a shock during transit, the EPS foam compresses in a controlled manner, effectively slowing down the deceleration and preventing that energy from reaching your product. This makes EPS custom packaging particularly valuable for fragile items like electronics, glassware and sensitive instrumentation.

This energy absorption isn’t just theoretical. Businesses using EPS packaging have reported damage rate reductions of up to 40% compared to other packaging methods. For high-value products, this reduction in damage translates directly to fewer returns, lower operational overhead and maintained brand reputation.

Unlimited Customization

The true power of EPS custom packaging lies in its almost unlimited design flexibility. Unlike off-the-shelf packaging solutions, EPS can be molded to accommodate virtually any shape, size or configuration. This means:

- Precision Contouring: EPS molds can capture even the most complex geometries, creating a nest-like environment that prevents movement during transit.

- Multi-Component Designs: For products with multiple parts, EPS can be engineered with separate compartments within a single package, keeping everything organized and protected.

- Density Variations: EPS packaging can be produced in various densities, providing extra protection where needed while optimizing material usage.

This customization extends beyond mere protection. Well-designed EPS packaging can improve the unboxing experience, incorporate branding elements and even serve as display packaging for retail.

The Business Case

Beyond product protection, EPS custom packaging provides tangible business benefits that affect multiple aspects of operations:

- Reduced Shipping Costs: The lightweight nature of EPS directly lowers shipping expenses, especially important for e-commerce businesses and companies shipping large volumes.

- Lower Damage Rates: With damage reductions of up to 40%, businesses save on return processing, replacement costs and potential customer dissatisfaction.

- Storage Efficiency: Custom-molded EPS packaging often requires less space than generic alternatives. This optimizes warehouse storage capacity.

- Sustainability Credentials: Despite common misconceptions, EPS is 100% recyclable and the industry has developed great recycling programs. Many manufacturers also use recycled content in their EPS production, which supports circular economy initiatives.

Industry Applications

EPS custom packaging has proven invaluable across many industries:

- Electronics: EPS provides both shock absorption and static protection from flat-screen televisions to sensitive medical devices.

- Medical Supplies: Temperature-sensitive pharmaceuticals and delicate medical equipment benefit from EPS’s thermal insulation and protective qualities.

- Food and Beverage: EPS keeps temperatures consistent for perishable goods during transit while preventing condensation issues.

- Industrial Components: Heavy but fragile automotive and mechanical parts receive protection from both impacts and environmental factors.

Choosing the Right EPS Partner

Not all EPS custom packaging providers offer the same level of expertise and quality. When selecting a partner, consider their design capabilities, material knowledge and experience with your specific industry. At Benchmark Foam, we work closely with clients to analyze their shipping risks, test different designs and develop solutions that balance protection with cost-effectiveness.

The most successful packaging partnerships involve collaboration from the earliest design stages through production and ongoing refinement. This makes sure that your packaging evolves alongside your products, continually providing the best protection while controlling costs.

Embracing the Future with EPS Custom Packaging

As supply chains become more complex and consumer expectations continue to rise, EPS custom packaging is a reliable solution that addresses many challenges at the same time. Its unique combination of lightweight protection, design flexibility and cost-effectiveness makes it an increasingly smart choice for businesses looking to protect their products and their profitability.

At Benchmark Foam, we’ve seen how the right packaging solution can transform our clients’ operations by reducing costs, minimizing damage and enhancing customer satisfaction. We believe that well-designed EPS packaging represents one of the most valuable investments a business can make in its product presentation and protection strategy.