A high-performance roofing insulation board helps create a stable, comfortable indoor environment. By effectively blocking outdoor temperatures, it allows heating and cooling systems to work efficiently and maintain comfort without strain. In an era of rising energy costs and growing environmental awareness, insulation has become a powerful tool for building owners and facility managers seeking […]

News & Articles

How a simple foam block is reshaping our built environment Think of a building method that completely changes how well a structure holds up against hurricanes, cuts heating costs dramatically, and resists fire for hours. This technology is not something we are waiting for. It is being used on construction sites right now, built one […]

In neighborhoods across Greater Sioux Falls, a quiet transformation is taking shape. One that replaces uncertainty with stability and builds not just houses, but homes filled with hope. Together with Stronghold ICF, Benchmark Foam is honored to join this mission through a partnership with Habitat for Humanity of Greater Sioux Falls, bringing the proven performance […]

Building heavy tech infrastructure on weak ground presents a major challenge. The Applied Digital data center in Ellendale, North Dakota, needed a structurally sound solution that could be installed quickly within its March-to-October 2024 schedule. The project required roughly 25,000 cubic yards of material to create a stable base. The answer was an unexpected one: […]

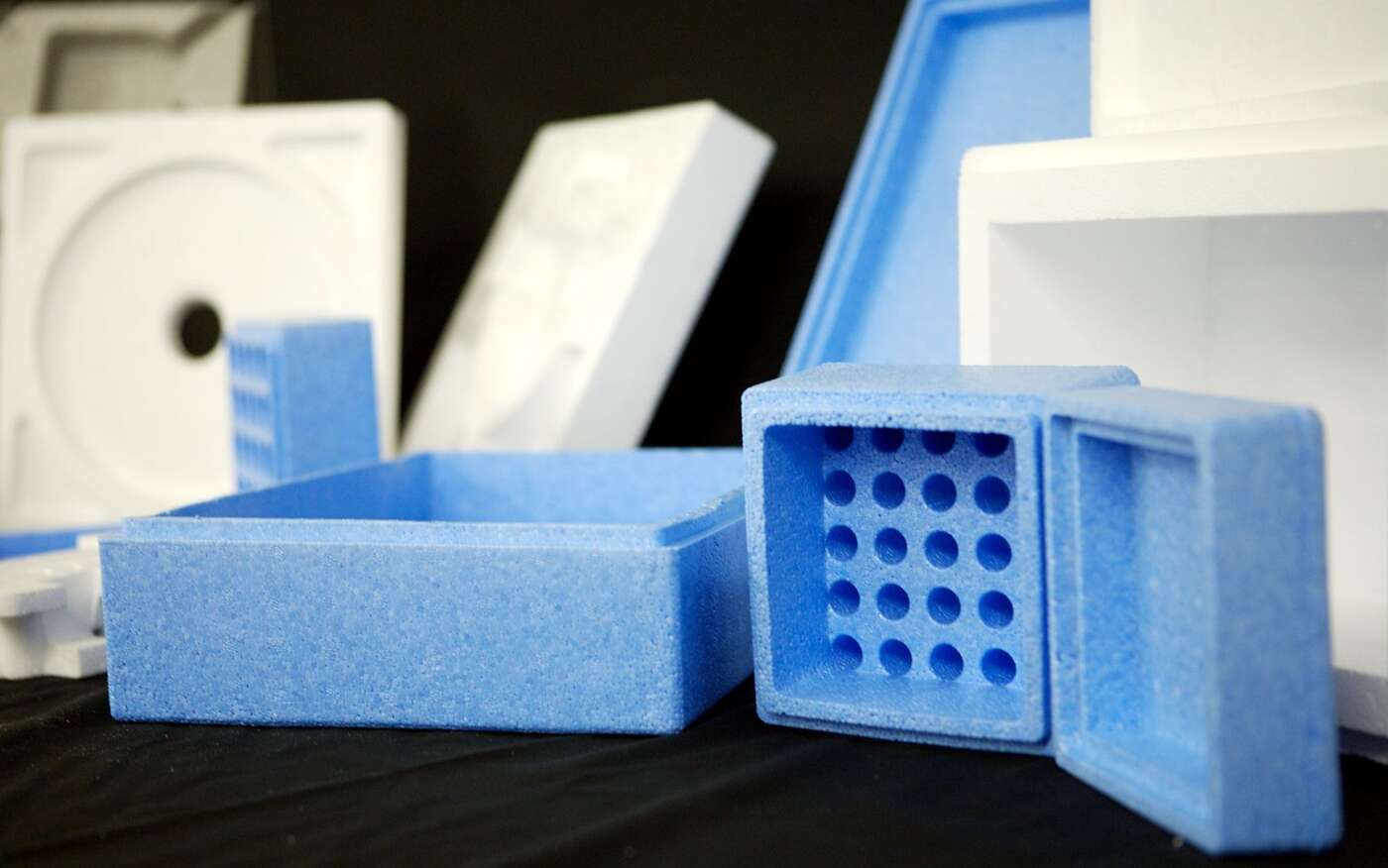

If you’ve ever unboxed a fragile electronic device or received a temperature-sensitive medical shipment in perfect condition, you’ve likely experienced the magic of EPS custom packaging firsthand. Expanded Polystyrene (EPS) molding represents one of the most effective methods for creating protective packaging solutions that seem to defy their own weight. At Benchmark Foam, we’ve spent […]

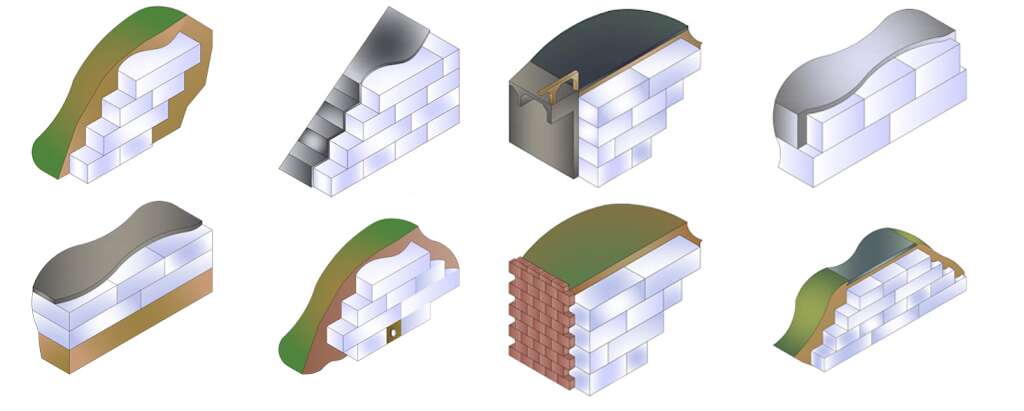

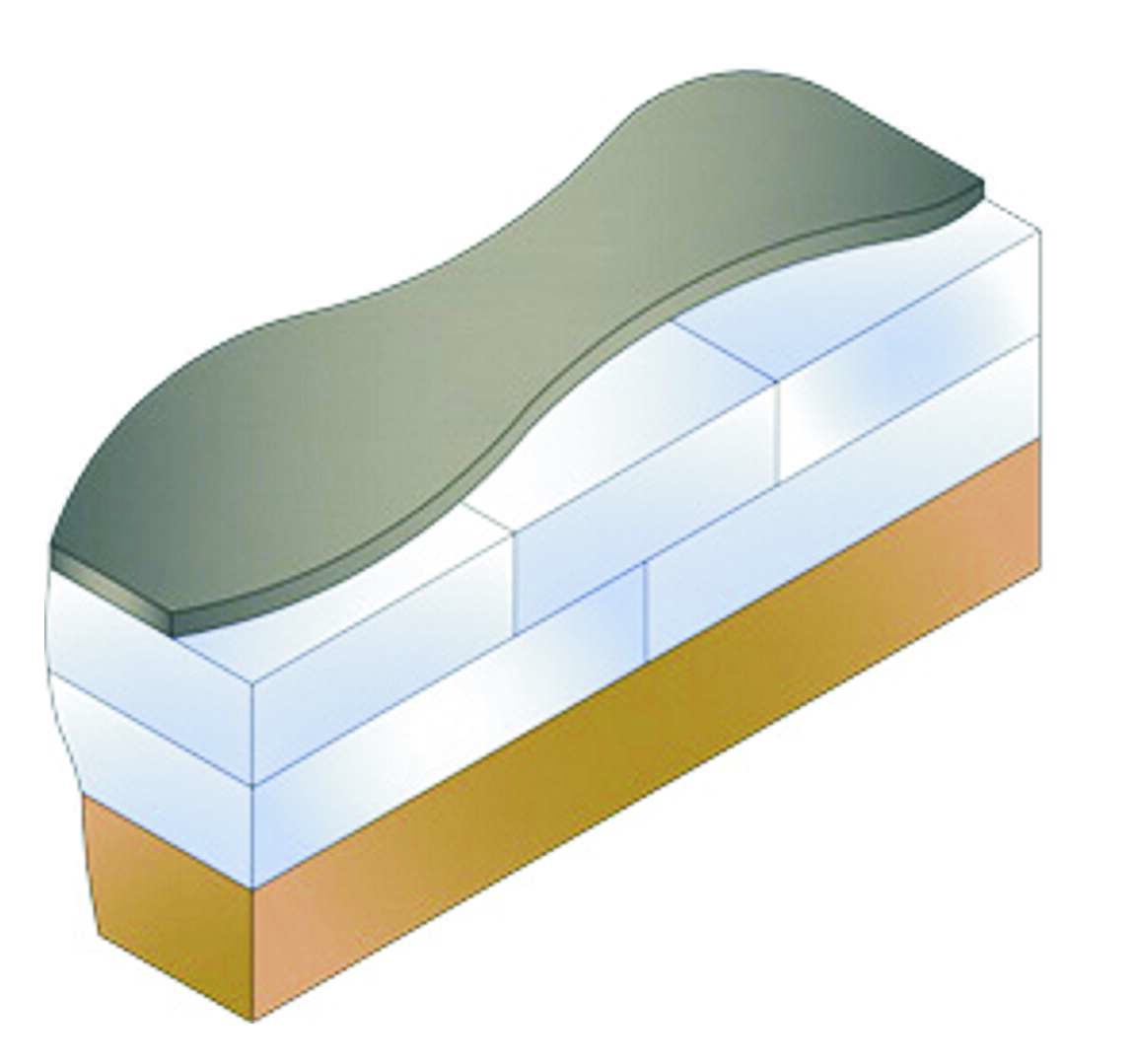

Weight matters when it comes to construction. Traditional fill materials like soil and gravel can add unnecessary stress to weak soils and lead to settling, shifting and costly repairs. That’s where Geofoam comes in. It’s a lightweight but strong material that’s changing the way engineers handle construction challenges. At Benchmark Foam, we manufacture high-quality Geofoam, […]

When it comes to choosing insulation, the debate between EPS (Expanded Polystyrene) and XPS (Extruded Polystyrene) is a big one. Both are made from polystyrene, but their differences in performance, cost and environmental impact can make or break a project. At Benchmark Foam, we know that the right insulation isn’t just about keeping heat in, […]

When storms rage, earthquakes shake the ground or temperatures swing wildly, buildings need more than just good looks. They need real strength. That’s where Stronghold Insulated Concrete Forms (ICFs) come in. Unlike traditional wood framing or even standard concrete construction, Stronghold ICF structures are built to stand firm when extreme weather strikes. From hurricane-force winds […]

At Benchmark Foam, we’ve seen firsthand how the right packaging can make or break a product’s journey from factory to customer. Cardboard and plastic have been standard packaging choices for years. However, molded EPS packaging can offer a better way. EPS is light but strong, saves money and can be recycled. The Problem with Traditional […]

Contractors face a tough choice when building on unstable ground: spend weeks (and a small fortune) moving heavy soil, or find a better way. That’s where Geofoam blocks shine. These lightweight yet sturdy EPS (expanded polystyrene) blocks are changing the game in construction, offering a simpler, faster, and more cost-effective solution for projects that need […]