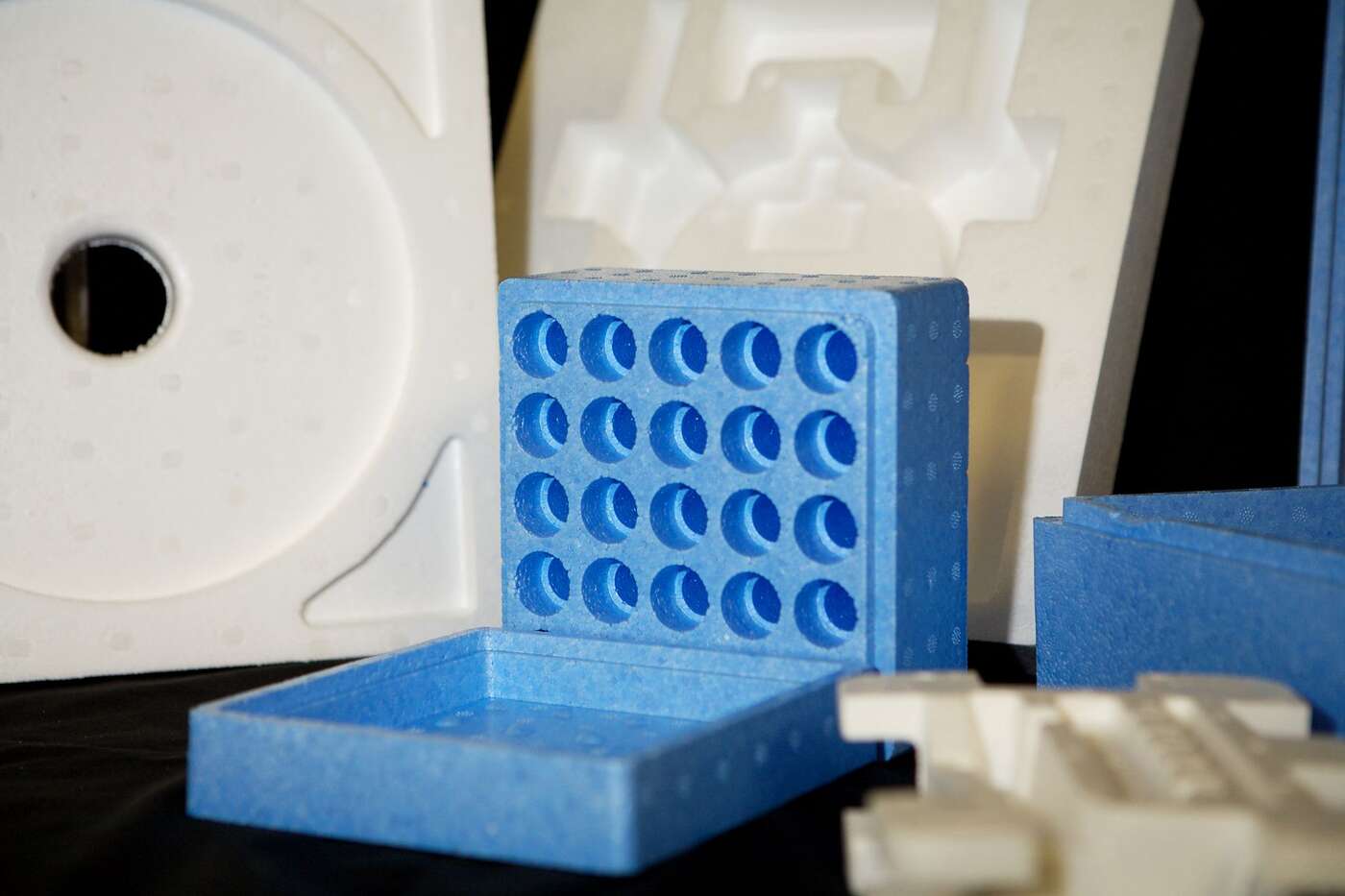

When you purchase a fragile item, chances are it’s protected by expanded polystyrene (EPS) foam. The secret behind its perfect fit is the EPS molding – a method that shapes foam into protective packaging with consistency and strength. From electronics to medical devices, this process delivers solutions that keep products safe.

One customer said, “Benchmark is a valued partner. Their product quality and commitment to customer service is a perfect fit with our strategic objectives.”

So how do expanded beads transform into structured packaging? Let’s walk through the steps.

How It’s Made:

1. Starting Small: Raw Material Prep

EPS begins as tiny polystyrene beads, each holding a small amount of pentane, a blowing agent. When heated with steam, these beads expand, growing much larger while remaining lightweight.

2. Shaping the Foam

The conditioned beads are placed into a mold and steam is applied again, softening the beads so they fuse together in the mold’s exact shape. The right amount of pressure ensures a solid, uniform structure.

3. Cooling and Releasing the Form

After molding, the foam must cool properly. Air or water help eject parts from the tool.

4. Finishing Touches

Once removed, each piece is checked for quality. The result is a snug-fitting, protective packaging component ready for use.

Why EPS Molding Is a Go-To for Packaging

Light but Tough

The light weight of EPS foam keeps shipping costs low, yet handles impact resistance well. It’s a favorite for delicate items like electronics and glass.

Keeps Temperatures Stable

Beyond cushioning, EPS resists heat transfer, making it useful for food containers and temperature-sensitive shipments.

Efficient Production

Parts can be used repeatedly, reducing waste and keeping costs manageable even for large orders.

Fits Any Design

Simple blocks or complex curves—EPS molding can match nearly any shape needed, making it a flexible choice for different industries.

Wrapping Up

EPS molding provides packaging that’s tough, adaptable, and cost-effective. By carefully controlling each step—expansion, molding, cooling—manufacturers create solutions that protect without adding bulk.

At Benchmark Foam, we rely on this process to deliver packaging that meets real-world demands. If you need protection that fits just right, EPS molding is a proven choice.