When it comes to building strong, energy-efficient structures, the materials and methods you choose make all the difference. For decades, traditional poured concrete has been the go-to for foundations and walls. But now, builders are turning to Stronghold ICF. It’s a smarter, more efficient way to construct durable, well-insulated buildings. So, what sets Stronghold ICF […]

News & Articles

When building roads and bridges, engineers face a constant challenge: how to create stable and long lasting structures without overloading weak soils or overburdening a budget. That’s where EPS Geofoam comes in. It’s a lightweight yet strong material that’s transforming infrastructure projects across the country. At Benchmark Foam, we manufacture high-quality expanded polystyrene (EPS) Geofoam, […]

When it comes to roofing insulation, not all rigid boards are created equal. The right roofing insulation board can make a significant difference in energy efficiency, comfort and even the lifespan of your roof. But with so many options available, varying in thickness, material and thermal performance, how do you choose the best one for […]

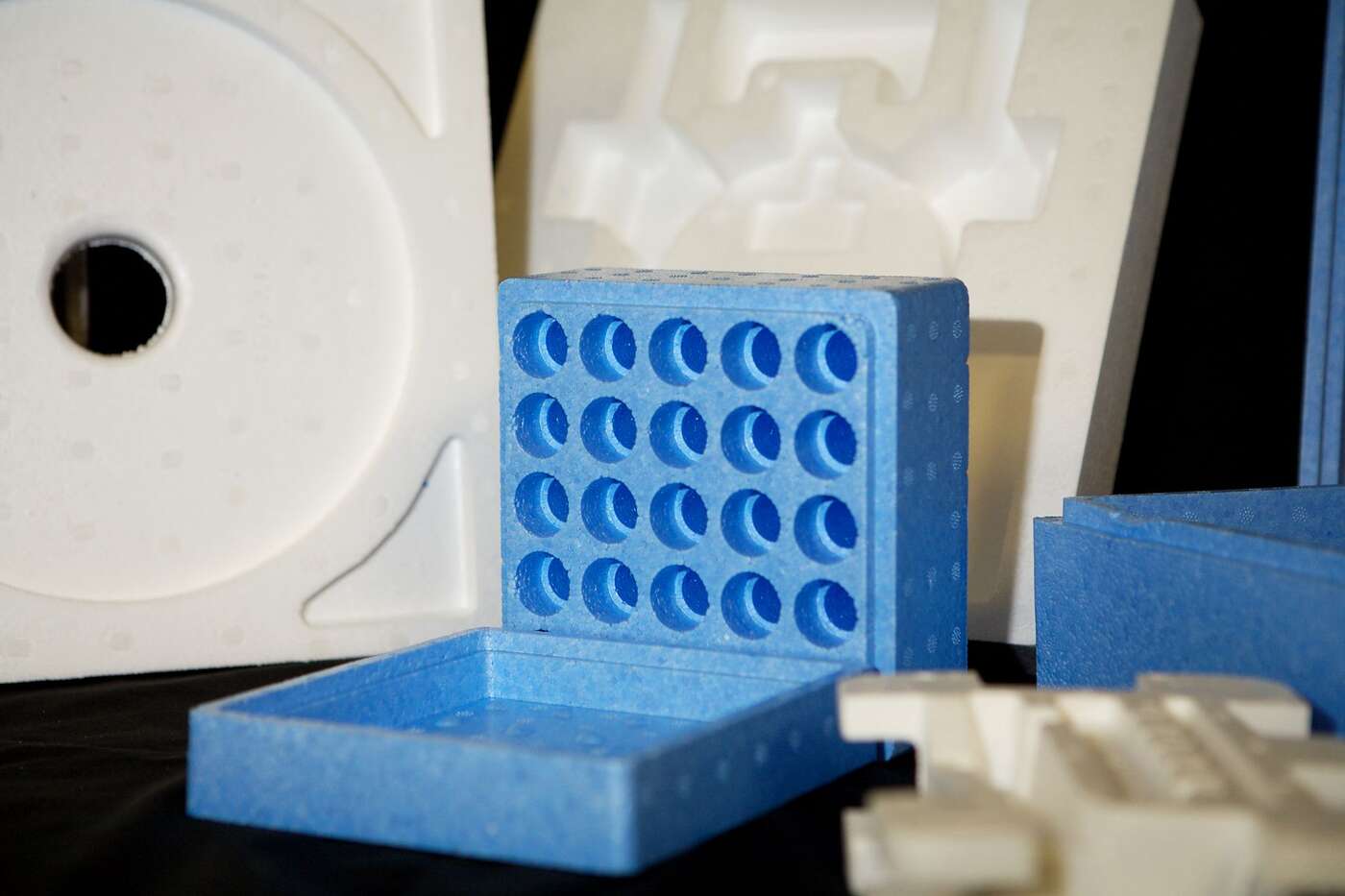

When you purchase a fragile item, chances are it’s protected by expanded polystyrene (EPS) foam. The secret behind its perfect fit is the EPS molding – a method that shapes foam into protective packaging with consistency and strength. From electronics to medical devices, this process delivers solutions that keep products safe. One customer said, “Benchmark […]

When products are damaged during shipping, it hurts more than just the bottom line—it impacts your reputation. That’s why more businesses are turning to custom EPS products for packaging that truly protects. Expanded polystyrene (EPS) foam isn’t just lightweight and cost-effective—it can be shaped, layered, and adjusted to cradle even the most delicate items securely. […]

In recent years, onshoring has become more popular. This is due to several things, like increased international tariffs, supply chain disruptions, and people beginning to support local economies again. At Benchmark Foam, we offer foam solutions for businesses that are choosing to manufacture closer to home. How Tariffs Affect Manufacturing Tariffs on imported goods have […]

Benchmark Foam now offers its patented Thermo-Snap in a 100% recycled option. Thermo-Snap 360® is a 100% recycled insulating panel that securely holds PEX tubing for in floor heat systems, bringing added sustainability to thermal performance. A smart alternative for environmentally conscious builders, Thermo-Snap 360® is produced from clean, dry, post-consumer expanded polystyrene (EPS). The […]

When Project Manager Tim Davis of Goss Foundations was contracted to build a radius concrete bench in front of the District 8 Federal Courthouse in Council Bluffs Iowa, his first call was to Sales Representative Matt Frey of Benchmark Foam. Due to the short time frame in which they needed to complete the job, Davis […]

There are many great reasons why a builder might choose insulated concrete forms (ICFs) for a project. The resulting structure will be more resistant to weather, insects and fire than its wooden counterpart. Concrete walls dampen sound better and often result in lower utility bills with a marked decrease in insurance premiums. The fall of […]

A 12′ foam-core replica work boot is featured on the cover of the March 2021 issue of Sign Builder Illustrated magazine. The boot was created by Signs By Benchmark, a division of Benchmark Foam, as part of a pole sign project for a boot and apparel shop in Michigan. Working with a design from Baker […]