Benchmark Foam Quality Assurance

Commitment to Excellence and Reliability

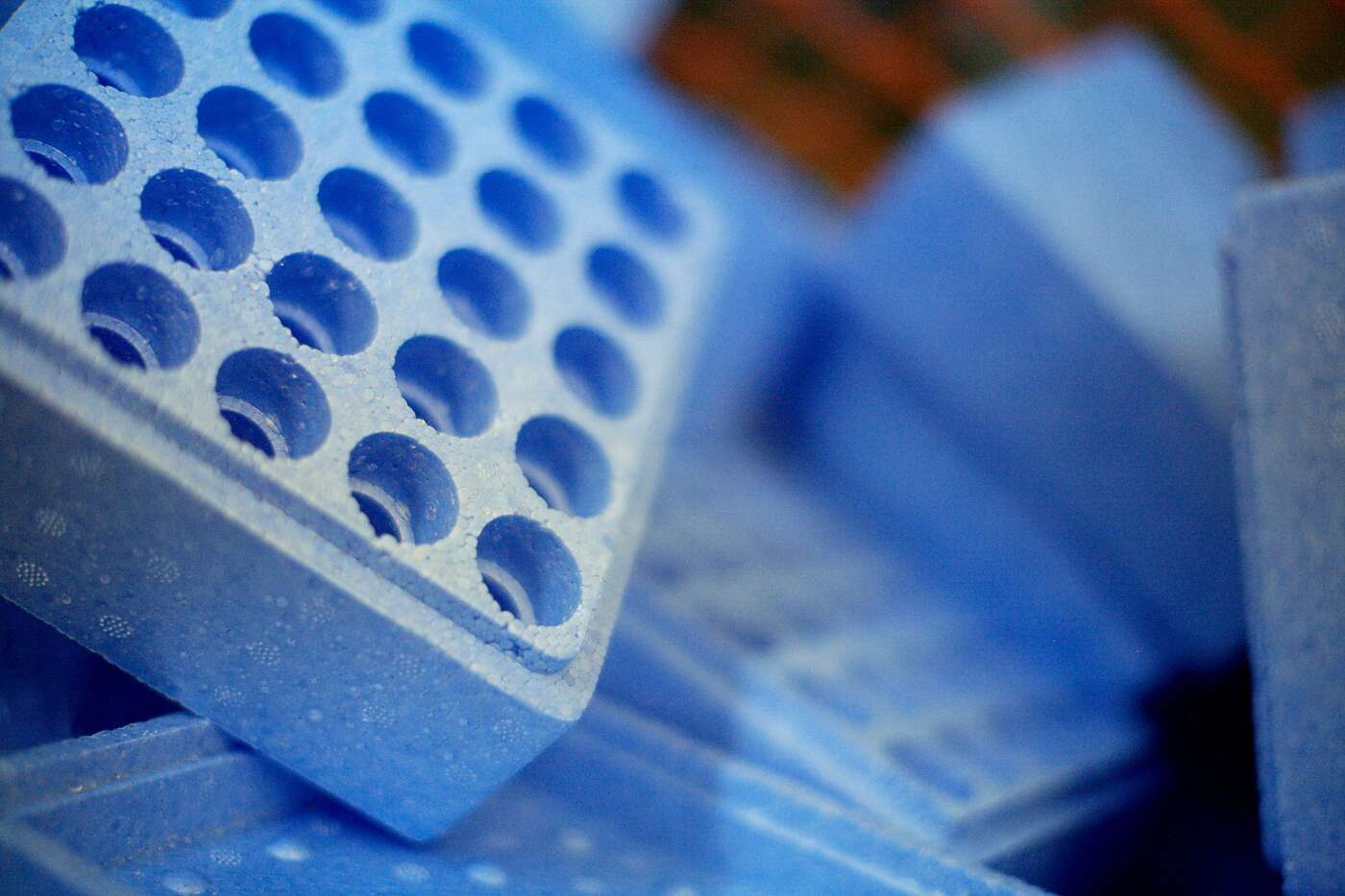

At Benchmark Foam, quality is the foundation of everything we do. As a prominent Expanded Polystyrene (EPS) foam manufacturer, we are dedicated to producing high-quality EPS solutions that meet the most stringent industry standards. Our commitment to excellence is visible in every aspect of our manufacturing process, from raw material selection to final product inspection. When you choose Benchmark Foam, you’re not just receiving EPS foam; you’re receiving EPS Foam Quality you can rely on.

Stringent Standards for Superior EPS Foam Quality

Our EPS products undergo rigorous quality control measures at each production stage to ensure consistent performance. We start by sourcing only the highest-quality raw materials from trusted suppliers. We use premium materials to ensure our EPS foam is both durable and reliable, providing effective insulation and protection for various applications. Benchmark Foam’s quality standards exceed industry requirements, enabling us to offer EPS foam that excels in energy efficiency, structural integrity, and environmental responsibility.

Our quality control team conducts thorough testing to assess our EPS foam’s density, thermal resistance, compressive strength, and moisture resistance. These tests help guarantee that our products meet specific customer requirements while delivering the insulation and durability needed for each project. This commitment to quality enables us to produce EPS foam products that are versatile, durable, and effective in applications ranging from building insulation to custom-molded packaging.

Specifications and Compliance

Benchmark Foam Stoop Fill meets or exceeds the structural standards of ASTM D6817-15 for EPS Geofoam, ensuring the highest quality and performance. The products are manufactured with certified EPS, which ensures product consistency and reliability.

Product dimensions are customizable and tailored to suit individual projects, helping ease particular construction plans.

Consistency You Can Trust

Consistency is essential for products that play a critical role in protecting valuable goods and maintaining building efficiency. Benchmark Foam maintains tight tolerances in our EPS manufacturing process to ensure that every product meets exact specifications. This focus on precision makes our EPS foam reliable in demanding environments, where performance is crucial to overall project success. Our consistent quality ensures that our EPS foam performs as expected, from construction to specialty packaging, no matter the application.

Customization for Quality-Driven Results

EPS products from Benchmark Foam can be customized to fit the needs of any project without sacrificing quality. Customers can choose the most suitable product from our EPS foam, which is available in different densities, thicknesses, and shapes. Our customization options ensure that your EPS foam product meets high quality and effectiveness standards, whether you need EPS foam for structural insulated panels, roofing insulation, or geofoam for construction fill. We manufacture each custom order according to Benchmark Foam’s quality criteria, so you know that your EPS product will meet your project’s needs.

Eco-Friendly and High-Quality Manufacturing

We prioritize environmentally responsible practices in our manufacturing processes without compromising on quality. EPS foam is inherently eco-friendly, lightweight, durable, and recyclable. At Benchmark Foam, we go further with products like our eps360®, made from 100% recycled EPS. Our facilities are designed to minimize waste and energy use, so our products contribute to a greener future. When choosing Benchmark Foam, you’re choosing EPS foam that aligns with your quality and environmental goals.

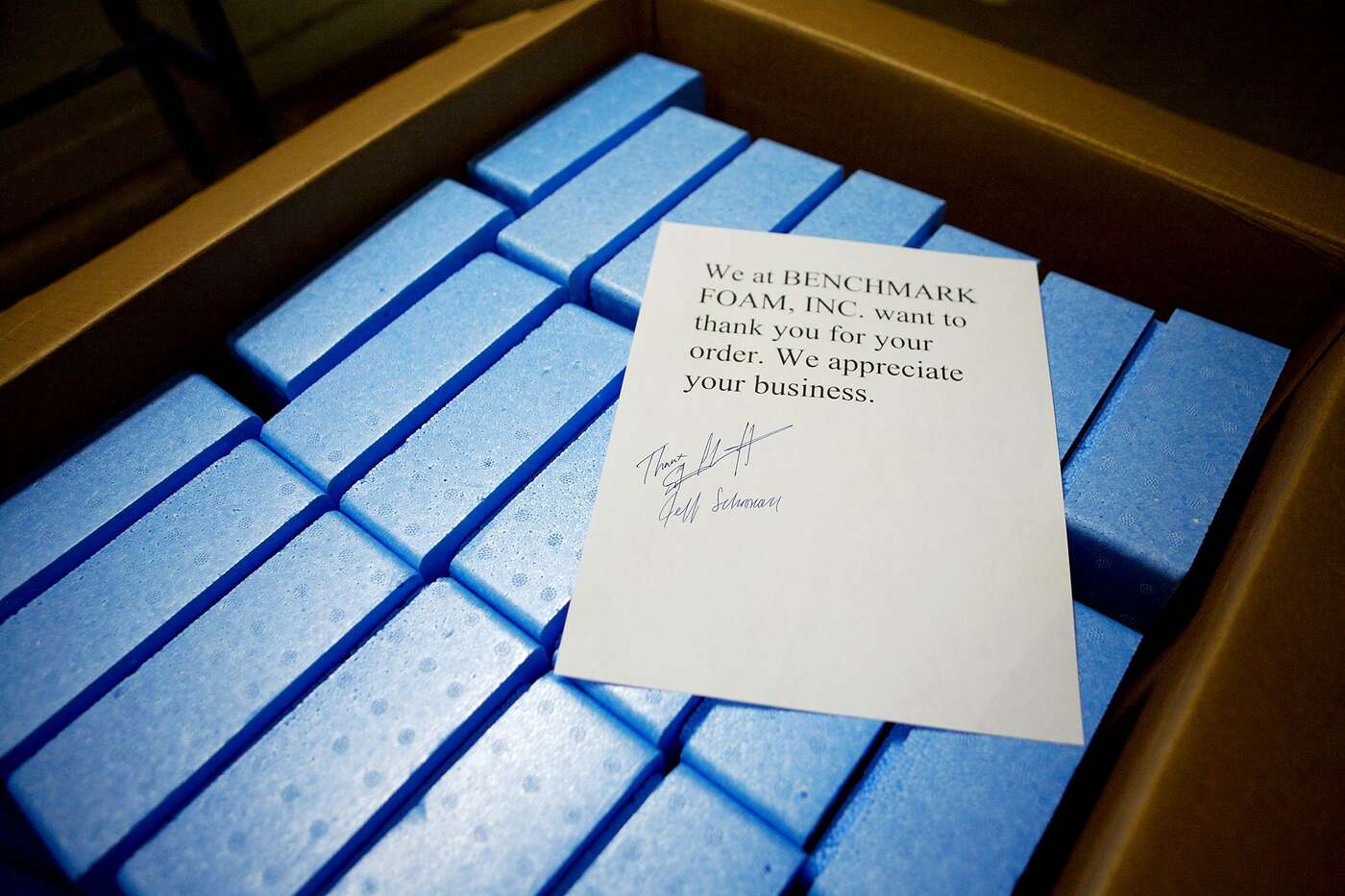

Benchmark Foam’s On-Time Guarantee for Reliable Service

In addition to providing quality EPS foam, Benchmark Foam is committed to delivering dependable service. Our On-Time Guarantee means your order will arrive as scheduled, or we’ll discount your invoice by 10 percent. This promise reflects our commitment to quality not only in our products but also in our customer service. Our team works closely with customers to ensure that every EPS order is completed to your specifications and delivered on time every time.

Discover EPS Foam Quality with Benchmark Foam

When quality matters, Benchmark Foam is your trusted partner. Our commitment to superior EPS foam quality, eco-friendly manufacturing, and reliable service sets us apart. Explore our range of EPS foam products and discover how our high standards can support your project’s goals.

Contact us today to learn more about our quality-focused EPS foam solutions and how they can bring value to your project.